PIX-Industrial Wrap Construction Belts

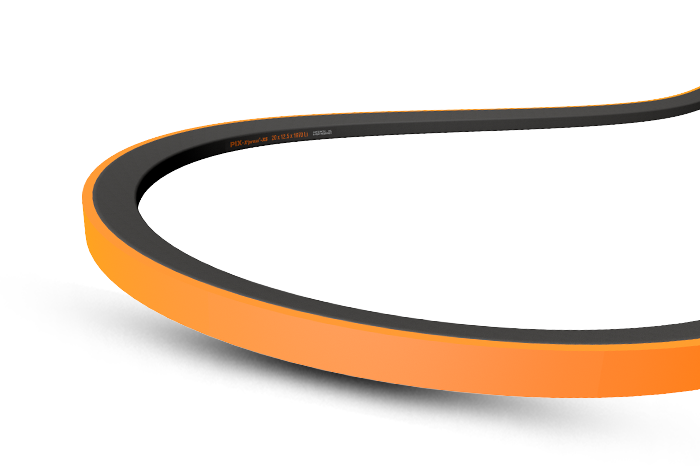

PIX is a pioneer in manufacturing various types of High Performance Belts. PIX has the global expertise in manufacturing the heavy-duty, High Performance, Industrial power transmission Belts for all those applications involving high power transmission, in compliance with all International Standards.

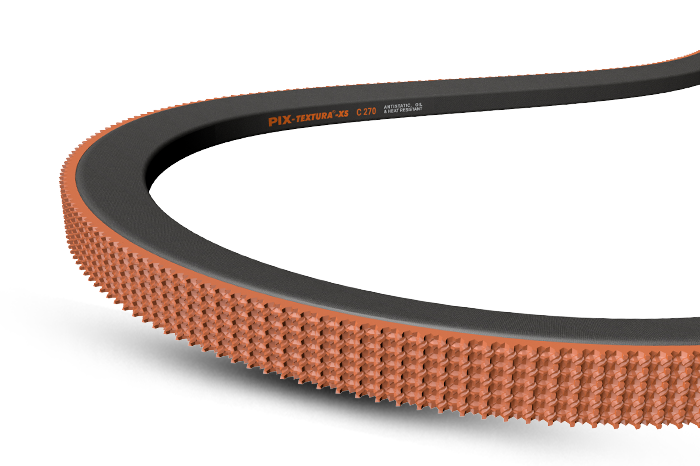

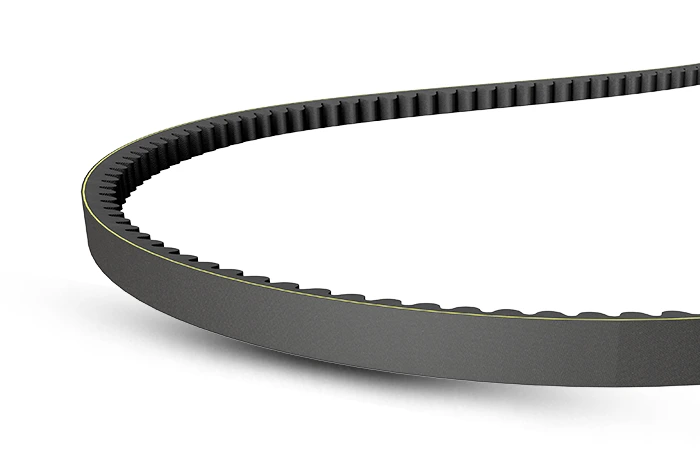

PIX High Performance Belts are available in Wrap, Raw Edge Cogged, Poly-V and in Timing Belt constructions. Enhancing its scope beyond the standard Belts, PIX has developed the Heavy Duty, High Performance Belts, Maintenance-free Muscle Series Belts in Wrap and Raw Edge Cogged constructions.

PIX Terminator Heavy-duty, High Performance Belts, Wrap Transmission Belts are available in dry-cover construction mainly for the mining application and they offer enhanced power transmission capacity up to 55% over the standard Belts. PIX-torqeuplus-XT2, heavy-duty High Performance Belts are available in timing construction, offering 50% to 70% enhanced power-rating over the standard HTD / STD sections of the Timing Belts.