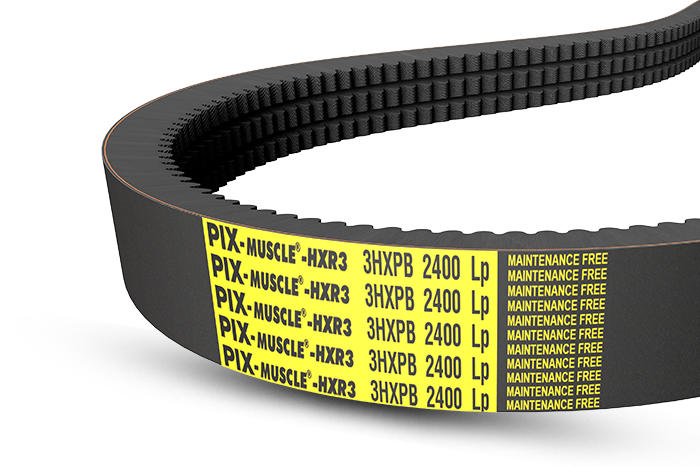

PIX-MUSCLE®-XR3 High-power, Maintenance-free Moulded Raw Edge Cogged Belts

Product Range

| Section | Top Width (Tw) (mm) |

Thickness (Th) (mm) |

Angle (θ) (Degree) |

Min. Pully Dia. (mm) |

Manufacturing Range | Length Designation | Additional Product Details |

|

|---|---|---|---|---|---|---|---|---|

| Min. (inch/mm) |

Max. (inch/mm) |

|||||||

| MF3-XPZ | 10.0 | 8.0 | 36 | 56 | 21.5 / 550 | 200 / 5000 | Lp | Click Here |

| MF3-XPA | 13.0 | 10.0 | 36 | 71 | 21.5 / 550 | 200 / 5000 | Lp | Click Here |

| MF3-XPB | 16.3 | 14.0 | 36 | 112 | 21.5 / 550 | 200 / 5000 | Lp | Click Here |

| MF3-XPC | 22.0 | 18.0 | 38 | 180 | 23.5 / 600 | 200 / 5000 | Lp | Click Here |

| MF3-3VX | 9.7 | 8.0 | 38 | 56 | 21.5 / 546 | 200 / 5000 | La | Click Here |

| MF3-5VX | 15.8 | 13.5 | 38 | 112 | 21.5 / 546 | 200 / 5000 | La | Click Here |

PIX’s overwhelming desire to be at the “Cutting Edge” in the Power Transmission field has culminated in the launch of the 'MUSCLE' range of maintenance-free Belts. Put simply, 'MUSCLE', is the ultimate V-Belt, offering superior-high power rating, Maintenance free Belts, and eco-friendly environment.Years of consultation with their customers and consideration of the changing world's requirements have resulted in PIX providing the "Perfect Solution".

PIX offers two types of Maintenance free Belts:

- PIX-Muscle-XS3 (High-power, Maintenance-free Wrap Belts), also available in Banded Belt construction

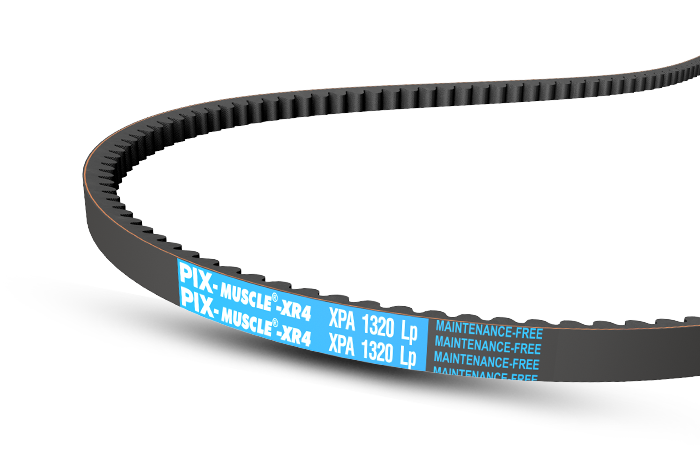

- PIX-Muscle-XR4 and PIX-Muscle-XR3 (High-power, Maintenance-free, Moulded Raw Edge Cogged Belts)

PIX Maintenance free Belts are produced to comply with the latest REACH directives & RoHS regulations.The special Belt compound does not emit any toxic substances, either during manufacture, or when running during use.The revolutionary design of the compound performs well in adverse conditions, such as high temperatures, UV or Ozone exposure, and chemically aggressive environments.MUSCLE shows remarkable performance characteristics in terms of elongation and slippage – minimising energy loss.These Belts are Maintenance free Belts, no re-tensioning is required.