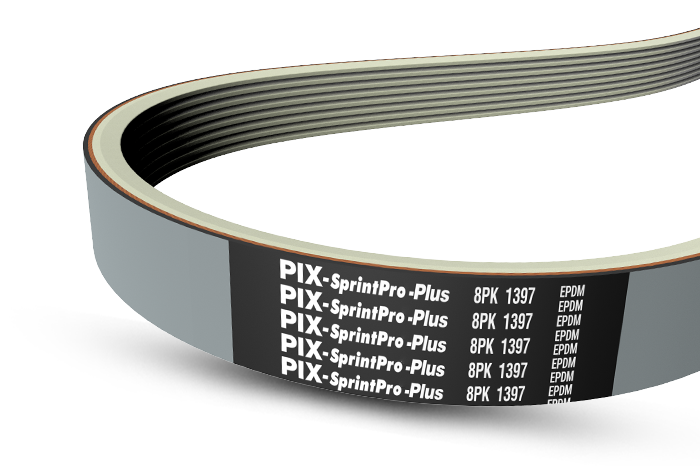

PIX-FORCE® Automotive Poly-V Belts

Product range

| Section | Thickness (mm) |

Rib Pitch (mm) |

Min. Pulley Dia. (mm) |

No. of Possible Ribs | Manufacturing Range | Length Designation | Additional Product Details |

|

|---|---|---|---|---|---|---|---|---|

| Min. (mm) |

Max. (mm) |

|||||||

| PK | 4.5 | 3.56 | 45 | 2 to 150* | 280 | 5000 | Le | Click Here |

| DPK | 7.0 | 3.56 | 50 | 2 to 13 | 1195 | 3255 | Le | Click Here |

Notes

* Belts are available in Moulded type: PK-710, 720, 730, 740, PK-750, 770, 800, 875, 930, 1035, 1040, 1045,1094, 1115, 1170, 1200, 1220, 1240, 1250, 1323, 1363, 1370, 1385, 1397, 1422, 1435, 1515, 1570, 1585, 1665, 1705, 1820, 1835, 1866, 2245

In olden days the engines used to be equipped with multiple Belts, performing varied functions. However, modern vehicles are designed to function fully using just a single V-Belt. It is mostly the Poly-V Belt or also known as Serpentine Belts, which is used to power the alternator, power steering, air-conditioning, and all other accessories.

The Serpentine Belts is either a V-Belt of a flat ribbed belt. The advancement in the technology and the rubber compounding has made the Serpentine Belts as the most reliable, single element to drive all the accessories associated with the engine.

The Serpentine Belts may solely operate the alternator or it may also drive other components such as water pump, air compressor, air conditioning compressor and power steering pump etc.