Pulleys

Features

- Manufactured from grey cast iron

- Pulley & pulley groove specification conforms to IS 3142 & ISO 4183 standards

- Ease of installation and removal

- Facilitates easy selection of different bore and key-way requirements

- Statically balanced

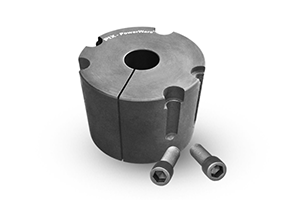

Bushes

Features

- Ease of installation and removal

- Facilities interchangeability

Product range

- 1008, 1108, 1210, 1215, 1310, 1610, 1615, 2012, 2517, 2525, 3020, 3030, 3525, 3535, 4040, 4545, 5050